Thermography

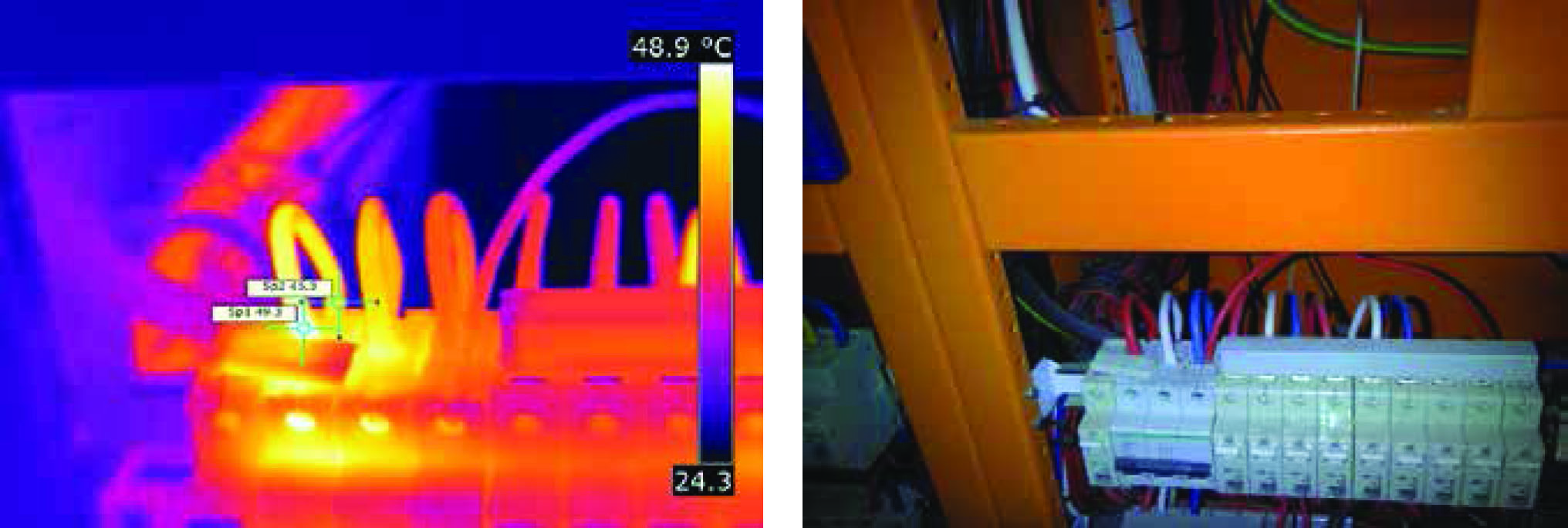

Infrared imaging systems use specially designed sensors to detect heat energy, which is invisible to the human eye and converts this into a visible picture. The picture is typically displayed in different shades of grey, or in a variety of colours, for qualitative temperature analysis of different components.

Infrared systems are especially use full for monitoring the condition of electrical panels and switchgear, LT and HT cabling and joints, transformers etc, and for monitoring for deterioration of refractory linings on furnaces. The technology is also useful for monitoring mechanical equipment such as bearings, motors, pumps etc.

Thermo tests can be conducted on the following:

a) Electrical panels and switchgear

b) Transformers

c) HT and LT cabling and joints

d) Deterioration of refractory linings on furnaces.

e) Monitoring of mechanical components e.g. bearings, motors, pumps, couplings.

f) On gear sets e.g. pinion and girth gears

Load Testing

To obtain maximum efficiency and trouble free operations, it is necessary to constantly monitor the equipment through detailed inspections and certification.

Load tests can be conducted for example on the following:

a) Overhead cranes

b) Chain blocks, lever hoists

c) Slings

d) Counter weights e.g. chairlift and conveyors

e) Lifting vehicles e.g. Manitou's, Truck mounted cranes, Forklifts, Mobi-lifts